FAQs

The classes of pipe represent the minimum D-load capacity a pipe produced to that class must have. The classes are designated in ASTM C 76, or AASHTO M 170. The required D-load capacity per pipe is as follows:

| Class | 0.01 inch Crack D-load (lbs/ft/ft) | Ultimate D-load (lbs/ft/ft) |

|

I II III IV V |

800 1000 1350 2000 3000 |

1200 1500 2000 3000 3750 |

The supporting strength of a pipe loaded under three-edge-bearing test conditions expressed in pounds per linear foot of inside diameter or horizontal span.

The complete procedure of the three-edge bearing test and how to calculate the D-Load are explained in ASTM Standard C497, Methods of Testing Concrete Pipe, Concrete Box Sections, Manhole Sections, or Tile.

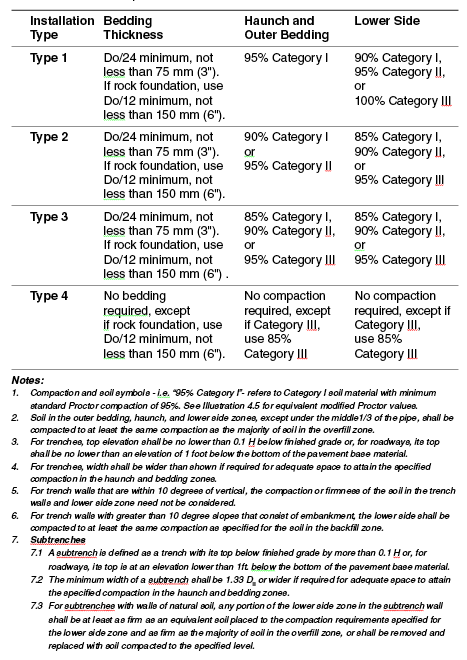

The four Standard Installations provide an optimum range of soil-pipe interaction characteristics. As a designer you can choose from a Type 1 Installation which requires high quality backfill material and compaction levels coupled with a lower strength pipe to a Type 4 Installation which utilizes a lower strength pipe because it was developed for conditions with little or no control over the fill materials or compaction. A Type 1 installation requires greater soil stiffness from the surrounding soils than Type 2, 3, and 4 installations, and is thus harder to achieve. Therefore, field verification of soil properties and compaction levels should be performed.

Soil and Minimum Compaction requirements for each Installation types are referenced shown in various AASHTO and ASTM standards:

The type of Installation required for the project will be based on a combination of factors such as available backfill materials, depth of fill, and required class of pipe. The American Concrete Pipe Association has PipePac software that can be downloaded free of charge. This software will help you analyze different Installation Types to help you decide on the most economical choice.

There are currently two acceptable methods by which concrete pipe may be designed: the Direct Design Method and the Indirect Design Method. The evaluation of the applied loads is similar for both methods, however, evaluation of the pipe’s capacity to resist the applied loads is different with the two methods.

The indirect design method is based on a relationship between the forces that are developed in the pipe wall when the pipe is installed and supported by soil versus the forces developed in the same location of the pipe when tested with the TEB method.

The direct design method follows the conventional design procedure for concrete members where demand versus capacity is determined using load and resistance factors.

Due to advancements in computer technology, the direct design method has become easier to evaluate than it was in the past. However, the indirect method which has been used for approximately 70 years has demonstrated conservatism and is a proven design method.

The minimum fill height requirements for concrete pipes is a function of the load being applied at the surface above the pipe, and the strength of the class of pipe provided.

The fill height of concrete pipes can be reduced to as low as the project requires, provided the pipe is designed to sustain the applied loads. In some cases where extremely heavy machinery will be traveling over the pipe, a concrete pipe with strength above the highest class of pipe denoted in ASTM C76 and AASHTO M170 may need to be utilized. This can be accomplished by working with your local producer. However, in most cases where an AASHTO HL-93 highway load is applied, and the fill height is equal to or greater than 1 foot of cover, a standard Class III pipe or greater will suffice.

For standard HL-93 highway loads, the required D-load at the specified fill height can be found in the ACPA Fill Height Tables. For other design load considerations, ACPA Design Data #1 Highway Live Loads on Concrete Pipe, the ACPA's Concrete Pipe Design Manual, and AREMA Manual for Railway Engineering can be consulted for design assistance.

Concrete Pipe can be installed in either a trench or embankment condition. The type of installation has significant effect on the load carried by the rigid pipe.

- Trench: When concrete pipe is installed in a relatively narrow trench, settlement between the backfill material and the undisturbed soil in which the trench is excavated, generates upward frictional forces. These frictional forces help support the backfill material within the trench, which results in a reduced load on the pipe compared to the weight of the prism of backfill material over the pipe.

- Embankment: In this condition the soil along the pipe wall will settle more than the soil directly above the pipe. This mechanism results in an increased load on the pipe compared to the weight of the prism of the backfill material over the pipe.

A Wall - The wall thickness in inches is the diameter in inches converted to diameter in feet.

B Wall - The wall thickness is an A Wall plus 1 inch.

C Wall - The wall thickness is an A Wall plus 1.75 inches.

ACPA’s Concrete Pipe producers follow strict quality control procedures to make sure they provide the highest quality to our nation’s infrastructure system. Requirements for manufacturing concrete pipes can be found in ASTM, AASHTO, and other standards and specifications.

The ACPA's quality control program, QCast, outlines guidelines for quality production and testing of concrete pipe. For any questions with regards to the manufacturing of concrete pipe contact your local manufacturer , schedule a plant tour, or contact ACPA.

ASTM Standards

- Indirect Design: ASTM C76 – 11 Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe.

- Direct Design: ASTM C1417 – 08 Standard Specification for Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe for Direct Design.

AASHTO Standards

- Indirect Design: AASHTO M 170-09 Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe.

- Direct Design: AASHTO Section 12 of the LRFD Code provides provisions to perform a direct design of concrete pipe.

ASTM Standards

- Standard Design Code: ASTM C 1433 Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers

- LRFD Design Code: ASTM C 1577 Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers According to AASHTO LRFD

AASHTO Standards

- AASHTO M 259 Precast Reinforced Concrete Box Sections for Culverts, Storm Drains and Sewers

- AASHTO M 273 Precast Reinforced Box Section for Culverts, Storm Drains, and Sewers with less than 2 feet of Cover Subject to Highway Loadings.

- No AASHTO LRFD Design Code exists. In the mentioned two standards you will find a note that states: “If load-and-resistance factor design is required, then use ASTM C 1577.”

For a full explanation on inspection see the ACPA “Post Installation Evaluation and Repair of Installed Reinforced Concrete Pipe.” Longitudinal Cracks–Concrete is strong in compression but weak in tension. Reinforced steel is provided to handle the tensile stresses. Hairline longitudinal crack in the crown or invert indicate that the steel has accepted part of the load. Cracks less than 0.01 inches in width are minor and only need to be noted in the inspection report. Cracks greater than hairline cracks, or those more than 0.01 inch in width but less than 0.1 inches, should be described in the inspection report and noted as possible candidates for maintenance. Longitudinal cracking in excess of 0.1 inch in width may indicate overloading or poor bedding.

A phenomenon, known as autogenous healing often occurs between two surfaces of cracks in buried concrete pipe. Autogenous healing is the ability of concrete to heal itself in the presence of moisture and air. This explains why the healing occurs in concrete pipe where moist conditions are higher than those of other concrete structures. During this process, calcium carbonate, (a hard white substance), forms when moisture reacts with un-hydrated cement powder and regenerates the curing process. This self-healing process creates a monolithic structure. In Ohio, the Department of Transportation developed a post construction inspection standard for installed pipe that requires nothing be done to a pipe with a crack width up to 0.06-inch, due to the autogenous healing that is expected to occur.

Concrete pipe is a rigid pipe that provides both structure and conduit when it arrives on site. Concrete pipe is a rigid pipe system that is over 85% dependent on the pipe strength and only 15% dependent on the strength derived from the soil envelope. The inherent strength of concrete pipe compensates for construction shortcomings and higher fill heights and trench depths.

Flexible pipe is at least 95% dependent on soil support and the installation expertise of the contractor. Backfill must be properly engineered and applied to provide structure. Imported fill is usually required for flexible pipe systems.

American Concrete Pipe Association recommended values of Manning’s “n” :

- 0.012 for a concrete pipe

- 0.012 to 0.024 for corrugated HDPE. It is recommended to use the higher range value to account for corrugation growth.

- 0.011 to 0.013 for PVC solid wall

- 0.029 to 0.034 corrugated steel pipe

- 0.016 to 0.018 for spiral rib steel pipe

The use of a rubber gasket does not by itself ensure that different joint types are equal. Designers can utilize ASTM Standards to specify for desired performance but in the case of alternate materials, additional guidance may be required. Concrete pipe joints are governed, in national standards, by better, more detailed designs with tighter tolerances and higher test pressures. Additionally, the project owner benefits from the concrete pipe joints’ inherent strength and rigid pipe design to enhance line and grade and assurance against deflection and buckling.

The American Concrete Pipe Association has a network of Regional Engineers who are connected with representatives of state concrete pipe associations and Technical Resource Engineers. You can contact reach out to your Regional Engineer by going to our Regional Information page. These representatives are available to present information to groups on a wide variety of design and quality control topics.

There are also education events throughout the year to share knowledge with people working in the buried infrastructure industry. Check out our Education Resources and the various events the ACPA is involved with on our Events page.

Plant tours are available year round for small parties or large delegations. Contact the American Concrete Pipe Association, or a local concrete pipe producer to arrange for a tour and information sessions.