How do I calculate the class of pipe required for my project?

You can either use the ACPA Fill Height Tables to look up the required class of pipe or download Chapter 4 of the Concrete Pipe Design Manual for a thorough explanation of how to calculate the required class of pipe.

What do the classes of pipe represent?

To make concrete pipe more readily available; rather than produce the pipe to the specific D-load required for every job, precast concrete pipe is often specified in terms of a generalized class system. The classes of pipe represent the minimum D-load capacity a pipe produced to that class must have. The classes are designated in ASTM C 76, or AASHTO M 170. The required D-load capacity per pipe is as follows:

| Class |

0.01 inch Crack D-load (lbs/ft/ft) |

Ultimate D-load (lbs/ft/ft) |

|

I

II

III

IV

V

|

800

1000

1350

2000

3000

|

1200

1500

2000

3000

3750

|

What is a D-Load?

The supporting strength of a pipe loaded under three-edge-bearing test conditions expressed in pounds per linear foot of inside diameter or horizontal span.

The complete procedure of the three-edge bearing test and how to calculate the D-Load are explained in ASTM Standard C497, Methods of Testing Concrete Pipe, Concrete Box Sections, Manhole Sections, or Tile.

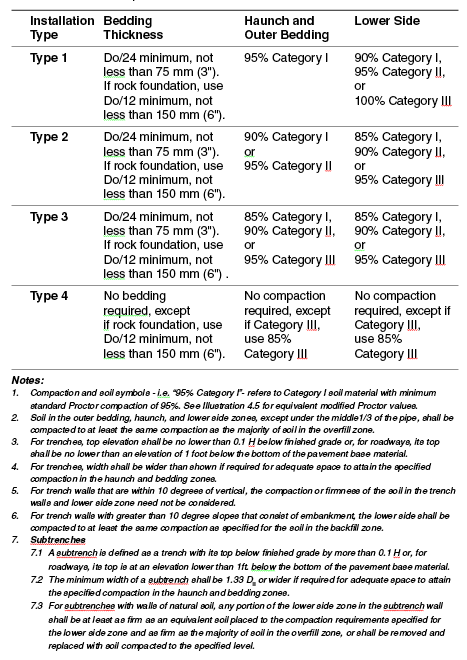

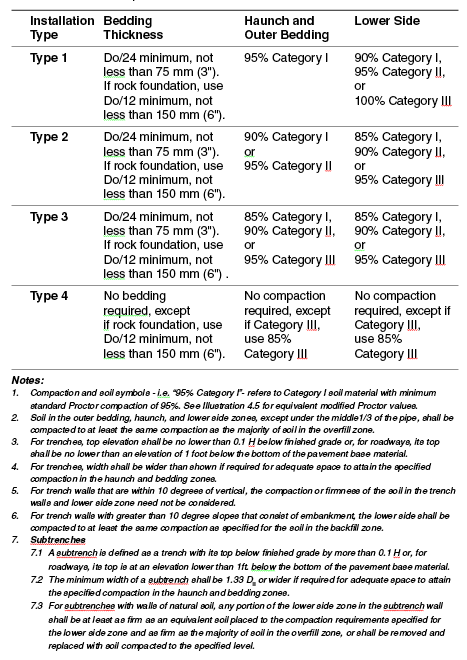

What are standard installations and which type would I use for my project?

The four Standard Installations provide an optimum range of soil-pipe interaction characteristics. As a designer you can choose from a Type 1 Installation which requires high quality backfill material and compaction levels coupled with a lower strength pipe to a Type 4 Installation which utilizes a lower strength pipe because it was developed for conditions with little or no control over the fill materials or compaction. A Type 1 installation requires greater soil stiffness from the surrounding soils than Type 2, 3, and 4 installations, and is thus harder to achieve. Therefore, field verification of soil properties and compaction levels should be performed.

Soil and Minimum Compaction requirements for each Installation types are referenced shown in various AASHTO and ASTM standards:

The type of Installation required for the project will be based on a combination of factors such as available backfill materials, depth of fill, and required class of pipe. The American Concrete Pipe Association has PipePac software that can be downloaded free of charge. This software will help you analyze different Installation Types to help you decide on the most economical choice.

What is the difference in Direct and Indirect Design for RCP?

There are currently two acceptable methods by which concrete pipe may be designed: the Direct Design Method and the Indirect Design Method. The evaluation of the applied loads is similar for both methods, however, evaluation of the pipe’s capacity to resist the applied loads is different with the two methods.

The indirect design method is based on a relationship between the forces that are developed in the pipe wall when the pipe is installed and supported by soil versus the forces developed in the same location of the pipe when tested with the TEB method.

The direct design method follows the conventional design procedure for concrete members where demand versus capacity is determined using load and resistance factors.

Due to advancements in computer technology, the direct design method has become easier to evaluate than it was in the past. However, the indirect method which has been used for approximately 70 years has demonstrated conservatism and is a proven design method.

When should I use Direct Design vs. Indirect Design for concrete pipe?

Indirect Design is the standard method for designing reinforced concrete pipe. It is a simplified method that corresponds to a pipe produced to a performance specification, whereby it is tested at the plant to verify its strength. When a concrete pipe cannot be tested to verify its strength in the plant, then the pipe structure must be designed similar to any other concrete structure using a direct design method that incorporates load factors and process factors into the design. If an engineer comes across a D-load of pipe that cannot be tested in the three-edge bearing test, either because the producer cannot apply sufficient load, or the pipe is too large to fit within the three-edge bearing test apparatus, then the engineer might want utilize the direct design method to design the pipe. Small diameter pipe should not be designed using the Direct Design Method due to the fact that the equations for direct design were originally formulated for larger diameters and therefore are overly conservative for the design of small diameter concrete pipe.

What is the minimum fill height I can bury a concrete pipe?

The minimum fill height requirements for concrete pipes is a function of the load being applied at the surface above the pipe, and the strength of the class of pipe provided.

The fill height of concrete pipes can be reduced to as low as the project requires, provided the pipe is designed to sustain the applied loads. In some cases where extremely heavy machinery will be traveling over the pipe, a concrete pipe with strength above the highest class of pipe denoted in ASTM C76 and AASHTO M170 may need to be utilized. This can be accomplished by working with your local producer. However, in most cases where an AASHTO HL-93 highway load is applied, and the fill height is equal to or greater than 1 foot of cover, a standard Class III pipe or greater will suffice.

For standard HL-93 highway loads, the required D-load at the specified fill height can be found in the ACPA Fill Height Tables. For other design load considerations, ACPA Design Data #1 Highway Live Loads on Concrete Pipe, the ACPA's Concrete Pipe Design Manual, and AREMA Manual for Railway Engineering can be consulted for design assistance.

What is the difference between a trench and embankment installation for rigid pipe installation?

Concrete Pipe can be installed in either a trench or embankment condition. The type of installation has significant effect on the load carried by the rigid pipe.

- Trench: When concrete pipe is installed in a relatively narrow trench, settlement between the backfill material and the undisturbed soil in which the trench is excavated, generates upward frictional forces. These frictional forces help support the backfill material within the trench, which results in a reduced load on the pipe compared to the weight of the prism of backfill material over the pipe.

- Embankment: In this condition the soil along the pipe wall will settle more than the soil directly above the pipe. This mechanism results in an increased load on the pipe compared to the weight of the prism of the backfill material over the pipe.

What is the maximum flow velocity I can design RCP without cavitation?

Velocity, by itself, does not create problems for concrete pipe within the ranges normally encountered. At velocities up to 40 feet per second, the severity of velocity-abrasion effects depends upon the characteristics of the bed load.

Does the American Concrete Pipe Association provide any guidance on designing precast box culverts?

Yes. The American Concrete Pipe Association has developed design notes for the design of precast box culverts in accordance with AASHTO LRFD. More design tools for box culverts can be found on our Design page or by contacting the ACPA.

How do I size the culvert required for my project?

Selection of the correct value for the coefficient of roughness of a pipe (Manning’s “n”) is essential in evaluating the flow through culverts and sewers. Selection of an excessive n value leads to an uneconomical design due to oversizing of the pipe, while an insufficient value results in a hydraulically inadequate sewer system. More information on calculating the hydraulics in a pipeline can be found in Design Data 11, Hydraulic Capacity of Culverts.

Does Concrete Pipe qualify for LEED credits?

Concrete pipe is suitable for LEED projects and it fits sustainable development. Unlike thermoplastic pipe, concrete is produced with benign, natural materials. Manufacturing of concrete consumes less energy than plastic fabrication. It’s also recyclable and has little if any environmental impact. And, when you use local resources, concrete can also provide lower fuel cost for delivery.

Why is it important to design concrete pipe to the 0.01-inch crack?

Reinforced concrete pipe, like other reinforced concrete structures, is designed to crack. It is well known that while concrete is very strong in compression, its tensile strength is so low that reinforcement is needed to withstand the tensile forces. Therefore, RCP design accommodates the high compressive strength of concrete and the high tensile strength of steel. As load on the pipe increases, and the tensile strength of the concrete is exceeded, cracks will form as the tensile load is transferred to the steel. Typically, the cracks form a V-shape with the largest part of the crack located at the surface. The presence of a 0.01-inch crack does not represent failure, but rather an indication that the concrete and reinforcement are working together, as designed.

What is the difference between service life and design life?

The National Cooperative Highway Research Program Synthesis of Highway Practice titled “Durability of Drainage Pipe” defines service life by the number of years of relatively maintenance-free performance. Webster’s Online Dictionary defines design life as the life expectancy of an item to work within its specified parameters.

What is the service life of concrete pipe?

The Army Corps of Engineers recommends a design life of 70-100 years for precast concrete pipe, and there are countless examples of installations that surpass those numbers. This means the expectation for precast concrete’s functional life is at least twice as long as alternate materials. The reasons for this go far beyond concrete’s innate strength. Concrete also won’t burn, rust, tear, buckle, deflect, and it’s immune to the attack of most elements, whether the pipe is buried or exposed.